Pneumatic and solenoid valves perform the same basic function: They modulate flow within industrial systems. But that doesn’t mean they are interchangeable. Installing the correct valve, constructed of the proper material, will determine whether your system functions or fails.

Pneumatic and solenoid valves perform the same basic function: They modulate flow within industrial systems. But that doesn’t mean they are interchangeable. Installing the correct valve, constructed of the proper material, will determine whether your system functions or fails.

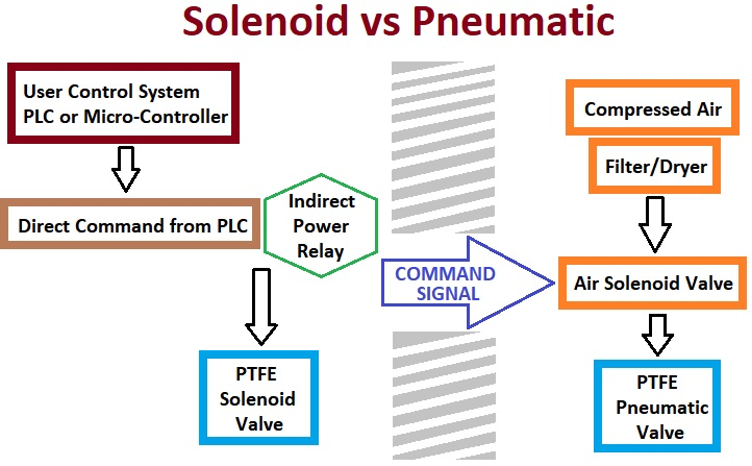

Pneumatic Actuation vs. Solenoid Actuation

While PTFE valve bodies are almost identical, the actuation is fundamentally different.

- PTFE pneumatic valves are actuated by a pneumatic actuator. The media working pressure for PTFE pneumatic valves can be greater because pneumatic actuators can generate larger forces and handle drive pressures (from 60psi to 100psi). The rate of actuation, speed of opening and closing, is 280ms to 450ms. Pneumatic actuators can drive PTFE valves as small at 1/16 inch to larger than 2 inches.

- PTFE solenoid valves are actuated by way of a solenoid actuator. Media working pressures are limited due to the strength of the magnetic field generated by the solenoid coil (which in turn creates the pulling force). The rate of actuation, speed of opening and closing, is much faster: 90ms to 190ms. The solenoid actuator limits the size of the available PTFE valve up to ½ inch.

- Another key difference between PTFE pneumatic valves and PTFE solenoid valves is how they are controlled. Solenoid valves can take a direct electrical signal from a controller or an indirect electrical signal from a power relay. The majority of time the user will include a small pneumatic air valve to trigger the compressed air, which will ultimately drive the PTFE pneumatic valve.

The Basics of PTFE Pneumatic Valves

Pressurized air, from the facility’s air compressors, should be filtered and dry before use within pneumatic devices. This compressed air is referred to as CDA. Automation system valves are signaled to open and allow the CDA compressed air to flow to the PTFE pneumatic valve. Once the inrush of air pressure becomes strong enough, it pushes against the actuator piston and actuator spring, moving the valve diaphragm and thereby opening or closing the valve. When air is exhausted, the valve actuation assembly moves in the opposite direction.

Our iPolymer PTFE Pneumatic Valve line features an all-PTFE wetted surface design ideally suited for harsh chemical and corrosive media and environments, as well as clean room and deionized water applications. The pneumatic actuator housing is designed into the main valve body for use within wet bench and extreme pH applications, such as:

- acid parts cleaning

- chemical delivery

- chemical neutralization

- deionized water rinse

- phosphoric acid nitride removal

- potassium hydroxide etching

- sulfuric peroxide stripping

- wafer etching

The Basics of PTFE Solenoid Valves

Solenoid valves consist of a coil, plunger and diaphragm assembly and are most commonly used to control the flow of liquid or gas. In a closed valve system, a spring holds the plunger in place to prevent flow. Once the solenoid coil is energized, the magnetic field raises the plunger to enable flow. The opposite is true in an open valve system. Solenoid valves are quick to open and close, and generally are used in smaller-diameter systems.

The all-PTFE wetted surface design of our solenoid valves is suitable for a wide range of ultra-clean to highly corrosive media applications—making them ideal for use in semiconductor, pharmaceutical, biomedical and chemical process applications.

Highlights:

- PTFE design optimized for ultra-clean and chemical compatibility;

- Available for DC & AC voltages;

- Fast, accurate and repeatable coil response time;

- High-duty cycle rated with controlled ambient temperatures;

- Valve seat and diaphragm for positive flushing and tight shut off;

- Nonporous diaphragm isolates solenoid coil from media;

- Designed for aggressive media and elevated temperatures.

At iPolymer, we pride ourselves on supplying the best pneumatic and solenoid valves available. We offer a great selection in addition to a highly knowledgeable staff who can help you find exactly what you need. Give us a call at 435.783.6040 or request a free quote.