When it comes to holding certain materials and shapes, using a vise isn’t always an option, or even the most efficient method. Some materials can be damaged or bowed by a vise, and set-up can be time consuming. On the other hand, using a vacuum chuck allows machining of five out of six full sides of a part; vises only allow exposure of three sides. Using a vacuum chuck also allows you to gain efficiency over using a vice by reducing non-value-added steps in the manufacturing process.

If you find that using a vise causes problems, a vacuum chuck is an ideal alternative.

Vacuum chucks are primarily used on non-ferrous materials, such as plastics and engineered polymers, like the ones we use at iPolymer to manufacture our products.

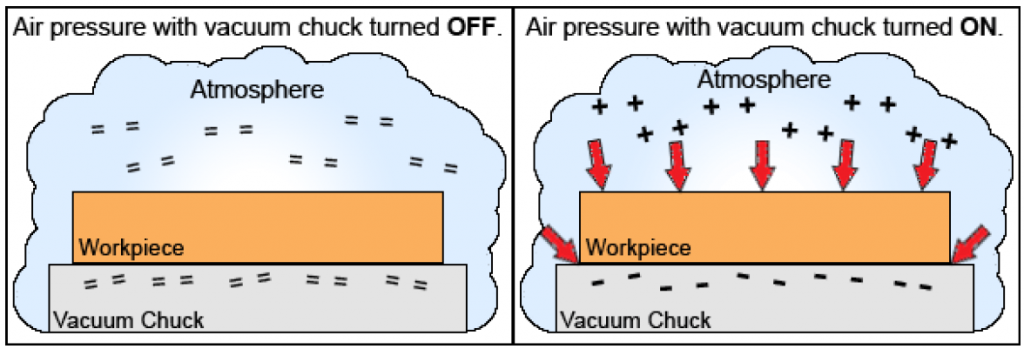

Despite the common explanation that vacuum chucks operate by sucking parts down, the truth is quite the opposite.

In a vacuum chuck, air is pumped from a cavity behind the work piece, and atmospheric pressure provides the holding force. The vacuum produces a hold-down pressure of 14.7 psi (101 kPa) at sea level, decreasing at higher elevations where the atmospheric pressure is lower.

Did you know that every square inch of our bodies has 14.7 lbs. of air constantly pressing on it when at sea level, and that our bodies have an internal pressure equally “pushing” out? This is why passengers on planes flying at high altitudes can experience swelling in parts of their body due to lower pressures in the cabin. Cabins are typically pressurized to an equivalent of being at 8,000 ft. above sea level. At this altitude, the air pressure is roughly 11 PSI. This is why work-holding with vacuum chucks at higher altitudes will experience a significant drop in holding force. A high-powered vacuum pump operating in outer space would be completely ineffective.

To sum it up, the atmosphere likes to remain at a constant level, and it is this principle that causes the wind to blow. Air flows from high pressure to low pressure. When objects are tossed around by the wind, they are acting as obstacles to this high-pressure-to-low-pressure flow. So when a vacuum chuck is turned on, the air pressure decreases below the work piece, which causes higher air pressure above the work piece to fill the low-pressure space below it. The work piece becomes an obstacle, which is pressed against the chuck and held tightly in place.