Chemical processing equipment is an essential part of producing critical media for several industries. Foods, beverages, oil and gas, chemicals, and even water are all processed through comprehensive chemical processing systems, using an array of advanced equipment. One of the most common pieces of equipment is the pneumatically actuated ball valve. At iPolymer, we specialize in delivering the very best fluid handling chemical process equipment to our customers across a wide range of industries. Narrow down your search further by referencing this quick guide on key types of pneumatically actuated ball valves.

Materials of Construction: Teflon (“PTFE”)

Compared to brass and stainless steel, Teflon (“PTFE”) Pneumatically Actuated Ball Valves are designed to handle extremely corrosive media. The materials of construction for the wetted flow path are exclusively manufactured from high-quality pure Polytetrafluoroethylene (PTFE). The PTFE Body, Ball, Stem, and Ports of the Valve ensure both corrosion resistance and minimal leachable exposure. High purity media for critical applications in semiconductor and pharmaceutical production cannot be exposed to brass or stainless steel. The PTFE Pneumatically Actuated Ball Valve offers an inert flow path that protests the media.

Two-Piece Construction

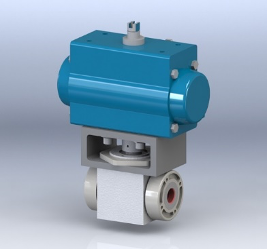

The most common type of construction for a PTFE Pneumatically Actuated Ball Valve is a two-piece design. A PTFE ball is placed within a PTFE body. Adding end ports and a stem completes the critical design components. A pneumatic actuator is added at the top of the valve, mounting to the stem and supported by the body.

These valves are easily maintained and can operate for several years maintenance-free. The Teflon on Teflon running surfaces ensure a low maintenance long life.

Actuator and Source Pressure

Pneumatically Actuated Ball Valves require a source control pressure to actuate the valve. While this is typically clean dry air (CDA), some applications call for Nitrogen (N2) gas. The actuation pressure drives the actuator mounted on top of the ball valve. These actuators can be configured for Air to Open and Spring to Closed, or Air to Open and Air to Close, or Spring to Open and Air to Close. The actuators can include end-of-travel limit switches and positive position indication. The most common Pneumatically Actuated Ball Valve is a quarter-turn (90-degree rotation) valve. The ball within the valve body is rotated by the stem and actuator 90 degrees from an open to closed position.

Alternate Body Configurations

While the PTFE Ball Valve is our most common configuration. Ball Valve bodies and stems can be manufactured from Polypropylene, PVC, and UHMW. Frequently the internal ball will remain manufactured from PTFE material. Some designs are configured with O-Ring seals, while others use a Double Split-V Ferrule configuration to seal the media from the outside world.

Semiconductor Wafer Processing Tools

Common applications for Pneumatically Actuated PTFE Ball Valves include main shutoff and blocking valves for harsh chemistry and DI water in Semiconductor Wafer Processing Tools.

Wafer Processing equipment frequently will daisy chain two, three, or four banks of tools together and use PTFE Ball Valves to feed chemistry from a common holding vessel to the tools. PTFE Ball Valves act as excellent blocking valves and main shutoff valves.

At iPolymer, we pride ourselves in supplying the very best in fluid handling process equipment. We offer a great selection of Pneumatically Actuated Ball Valves, with a knowledgeable staff that can help you find exactly what you need. Give us a call at 435.783.6040 or request a free quote.