Chances are high that if you work in any type of laboratory or manufacturing environment with liquids or gases, you are probably familiar with a range of classic pneumatic valves. For a quick refresher: pneumatic valves help to control, manage and handle the amount of media, liquids and gases, which flow through a system.

Types of Pneumatic Valves

Fundamentally, there are two very different types of pneumatic valves. The first pneumatic valve type is where air or an inert gas is the pneumatic drive force. These type of valves control or manage the source air within an automated system. While frequently referred to as pneumatic valves, they can be actuated (operated) by manually, by pneumatic actuation, by solenoid actuation, or by motorized actuation. Ultimately, they all serve the same purpose: they modulate or control the source air for an automated system. Depending on the system specification and plumbing line size, these pneumatic valves can be of a gate, plug, diaphragm, wedge, or ball design, to name a few.

These valves can be actuated on a variety of methods, but their function is to handle the drive air or inert gas. These pneumatic valves are frequently controlling, managing or handling Clean Dry Air (aka CDA) for a manufacturing process. The CDA or source air drives other pneumatic devices (valves, pumps or other actuators). Those pneumatic devices in turn may be modulating process media or moving mechanical systems.

The second type of pneumatic valve is one where the media is a process fluid or gas, which is being controlled, managed or handled by the valve. The valve has a pneumatic actuator which is driven by air or an inert gas (aka CDA). The CDA or source air drives the pneumatic valve to position (open, closed or some partially open position). The pneumatic valve, connected to its pneumatic actuator, will modulate the media flowing within the process.

Both pneumatic valves for automation control and process fluid handling remain very common in industry. While they have seen some displacement by way of electro-mechanical (servo & stepper motor driven) and hydraulic driven system, pneumatic actuation remain a cost effective method of actuating valves. For many applications pneumatics are preferred; for example, within the semiconductor industry pneumatic systems run cleaner with less positive-charged ions from metals. Within the life science industries, pneumatic systems run more sanitary for food and human safety.

Configurations of Pneumatic Valves

A further distinction within the types of Pneumatic Valves available in the market can be found within their porting configuration. Pneumatic Valves can be ported in a wide range of configurations. The industry segments valve porting into three major classifications: the port size, the port style and the ways of the valve.

- Port Sizing: Pneumatic Valve port sizes can vary from less than 1/16” to greater than 48” in diameter

- Port Styles: Pneumatic Valve port styles are categorized into Socket, Threaded (NPT, BIS, JIS, DIN et al), Compression Tube, Flare, Sanitary, and many other unique port arrangements.

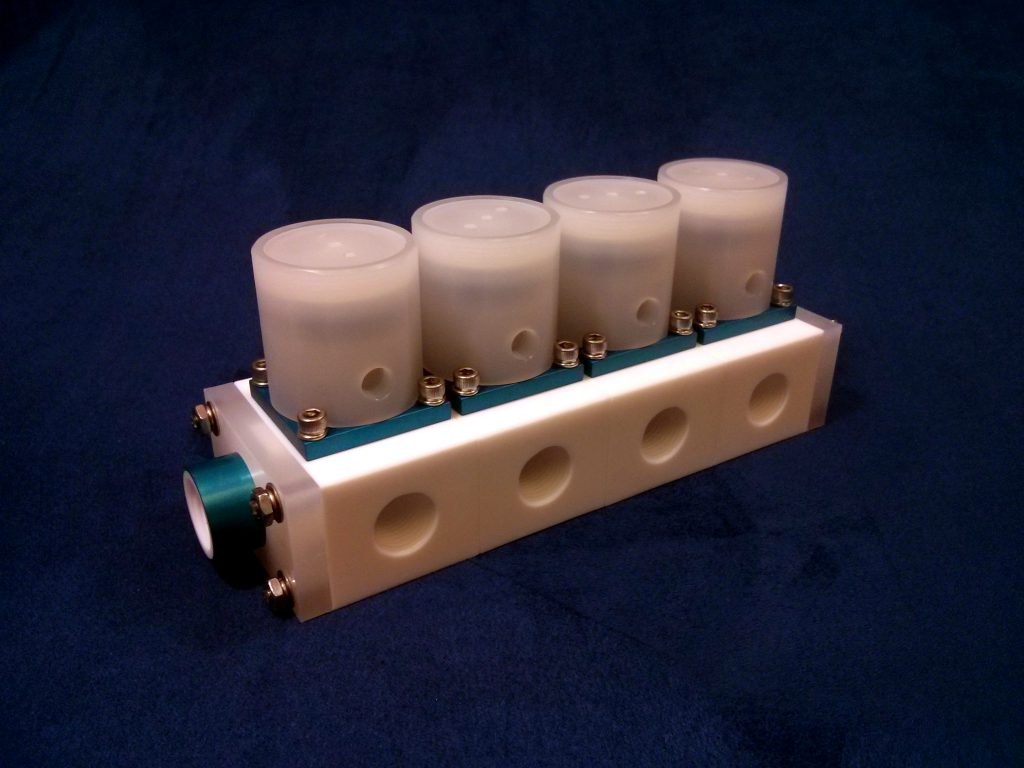

- Port Ways: Pneumatic Valves can be design and manufactured as a 2-Way (the most simple inlet and outlet valve), 3-Way, 4-Way, and even greater number of ways. Multi Way valves are frequently used as Selection or Distribution Valves. Where one way is dedicated as the inlet or outlet of the valve and the other multiple ports (or ways) represent the selection or distribution of media flow.

Pneumatic Valve Materials of Construction

Pneumatic Valves for automation control live outside the process media. They are typically manufactured with a mix of material, which include: plated carbon steel, bronze/brass, stainless steel, and a wide range of industrial grade plastics (PVC, Nylon, Acetal, etc.)

The driving pneumatic media or gas (typically CDA air or inert gas) for an automation control pneumatic valve is highly conditioned, filtered, and dried. Therefore the valve design does not have to consider the aggressive corrosive nature of the media or account for the high purity level of the media.

Whereas, the Pneumatic Valves for process fluid handling the media is key. The media is one of the key selection criteria for choosing the pneumatic valve. These valves handle highly acidic, corrosive alkaline and/or high purity media. The designer must select materials of construction for all wetted surface of the valve, which are exposed to the media, to both protect the media and the valve. Whether the Pneumatic Valve is handling 85% Sulfuric Acid or 18MegaOhm DI Water, the design must protect the media.

Polytetrafluoroethylene (PTFE) as a Construction Material

Pneumatic Valves for process fluid handling must first and foremost consider their materials of construction. PTFE Pneumatic Valves are manufactured for critical media process handling. The PTFE valve body and diaphragm, or bellow or plug is configured to ensure the media only contacts virgin pure PTFE. Certified virgin pure PTFE material is the original sintered Polytetrafluoroethylene (PTFE) without any type of impurity or regrind or recycled plastic.

PTFE Pneumatic Valves can handle the harshest low pH acid, the most corrosive high pH alkaline, and the purest of media. By its nature PTFE is exceptionally inert and highly chemical resistant. It is frequently one of the best material options for Pneumatic Valves for process handling of critical media.

In later articles we will study the process manufacturing of Teflon® (the former trademark of Dupont). Teflon® is the world known brand name for Polytetrafluoroethylene (PTFE). We will explore where PTFE get its great chemical resistance, temperature performance, low friction properties and exceptional inertness.