Hydrogen Chloride (or HCL gas), is a toxic gas which is important in the semiconductor industry. HCL has many other uses; for instance, it’s used to produce certain chemicals, metals, petroleum, textiles, and even some food products such as gelatin, soy sauce, and vegetable protein. At room temperature, it’s a colorless gas with a rather pungent smell. When dissolved in water, it is one of the strongest known and toxic acids. And, when it reacts to common metals it yields hydrogen, which can be explosive when it comes in contact with air. Continue reading Post ID 131

- Category Archives iPolymer

-

-

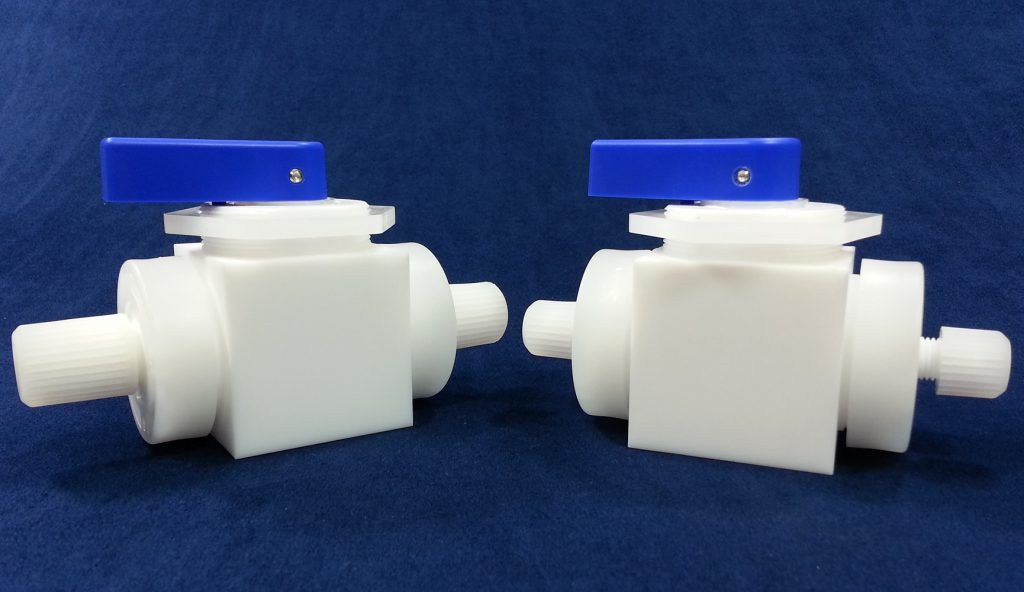

Common Pneumatic Valve Types for Engineers

Common Pneumatic Valve Types for Engineers

Chances are high that if you work in any type of laboratory or manufacturing environment with liquids or gases, you are probably familiar with a range of classic pneumatic valves. For a quick refresher: pneumatic valves help to control, manage and handle the amount of media, liquids and gases, which flow through a system. Continue reading Post ID 131

-

6 Acid Resistant Materials That Can Be Used Effectively in a Lab

Whether you work in the pharmaceutical industry or chemical manufacturing, finding acid resistant materials to create safe and compliant laboratories or manufacturing facilities is an important part of the job. Luckily, for those of us that work in cleanroom environments, that are plenty of acid resistant materials to choose from and the varying benefits of each can help you figure out which one is best for your specific use case.

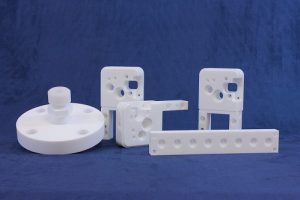

1. PTFE (or Teflon™) – PTFE, also commonly known as Teflon™, is one of the most acid resistant materials available and is commonly used in chemical and pharmaceutical lab applications. Aside from being resistant to many acids used in labs, most people know PTFE (or Polytetrafluoroethylene) as one of the best materials for low friction properties. In fact, it has the second lowest co-efficient of any known solids aside from diamond-like carbon (DLC). What many people don’t know, however, is that PTFE as a lubricant can offer reduced friction in the form of less wear and tear and energy consumption on manufacturing equipment and machinery. And in more stringent healthcare applications, PTFE coatings can minimize the risk of bacteria sticking to hospital equipment, effectively reducing the likelihood of spreading infections.

PTFE Ball Valve from iPolymer. 2. Hastelloy® – Hastelloy® is a metal superalloy that’s highly resistant to acids, but is primarily used in very niche applications within the aerospace, chemical processing, and industrial gas turbine industries. That’s because Hastelloy® offers the added benefit of working well with high pressure and temperature characteristics. Because Hastelloy® is great for high temperature and high stress environments, like inside of chemical reactors, it’s one of the most expensive acid resistant materials. Given its high cost, it’s not always the most optimal solution for most labs – unless you’re working in a highly corrosive environment.

3. PVDF – Polyvinylidene (or PVDF) is an acid resistant material (though not as resistant as PTFE) that’s used for a lot of different high purity applications. It’s more flexible than some of its acid resistant counterparts, such as PTFE, and can be injected, molded or welded. Because of its flexibility, it’s often used as an insulator for wires and as piping for high purity liquids. PVDF isn’t as resistant to temperature as other acid resistant materials, so that hinders its ability to work in a wide range of chemical and pharmaceutical lab cases.

4. Polypropylene – Polypropylene is a thermoplastic polymer that’s rugged and resistant to many acids. It can also function as both a plastic and a fiber, and because of that has one of the largest varieties of applications of all plastics. The fact that it’s relatively cheap to produce also doesn’t hurt. You’ll almost always find polypropylene in small plastic parts for consumer electronics and household appliances, but because of its acid resistant properties, it’s also a popular choice for lab equipment.

5. PEEK – Polyether ether ketone (PEEK) is a sturdy semicrystalline thermoplastic that can stand up to high temperatures. It can be machined almost like metal, so it’s used in applications that are more demanding, such as electrical cable insulation, piston parts, bearings, pumps, and compressor plate valves. These days, new developments in PEEK processing have given it the ability to have shape-memory behavior, which has a lot of applications in orthopedic surgery. PEEK is more cost prohibitive to work with, though, so it’s usually only used in very specific applications.

6. PFA – Perfluoroalkoxy alkane (or PFA) is an acid resistant material whose primary claim to fame is its ability to be injection molded. It’s highly corrosion resistant, so it’s most often used in working with aggressive chemicals. It has properties that are very similar to PTFE, but it’s ability to be melt-processed give it an advantage in applications that require injection molding. Because of this, though, it can be expensive to customize.

-

PTFE Diaphragm Valve Advantages in the Pharmaceutical Industry

Pharmaceutical research has come a long way over the last few decades. And with it, so have pharmaceutical laboratories and manufacturing facilities. With an increasingly competitive industry, any small improvement in lab processes and manufacturing setups can mean big gains for R&D and eventually, the bottom line. So it’s no surprise that modern pharma labs and pharma production facilities are veritable gold mines of high-tech lab equipment designed to improve efficiency and minimize errors.

Despite that, it seems that there are still some kinks in the quality control department to work out. A 2014 study by the US Government Accountability’s Office found that the most often cited reason for drug shortages and delays was an issue in quality control in the manufacturing process. In fact, an FDA Staff Report from 2012 showed that weaknesses in sterile injectable drug manufacturing had caused nearly a third of the total biopharmaceutical industry’s production capacity to be taken offline. When you’re dealing with hundreds of millions in potential drug revenue, that’s a huge loss – and one that most pharmaceutical companies can’t afford.

For some manufacturing industries, large machinery maintenance plays a major role in minimizing downtime and keeping the manufacturing process rolling. However, for pharmaceutical research and manufacturing, often you’re dealing with high purity compounds, where one small malfunctioning piece of equipment can mean losing or contaminating an entire production run.

With these types of pharmaceutical applications, a PTFE diaphragm valve offers a wide range of advantages over the alternatives. One of the biggest advantages being the high cycle life that allows PTFE diaphragm valves to stay functional and in good working conditions much longer than other types of materials. In fact, PTFE offers a few strong advantages when it comes to the diaphragm valve use in the pharmaceutical industry.

- Chemical compatibility – A PTFE diaphragm valve has a high chemical compatibility, meaning it can work with and safely stand up to a wide variety of chemicals and chemical compounds. In pharmaceutical applications, this means that PTFE diaphragm valves are incredibly versatile and and can be used for many different tests, experiments, and manufacturing processes.

- Low friction properties – PTFE has a low coefficient of friction, which makes it an ideal choice when you’re trying to avoid unnecessary wear and tear in a pharmaceutical manufacturing setup. This can result in a much lower part replacement costs and less downtime due to maintenance.

- Low surface adhesion – While other materials can create issues when it comes to surface adhesion, PTFE has a low surface adhesion which means that when pharma researchers are working with pills or powders, it doesn’t stick to the materials. And when working with liquids, it minimizes coagulation.

These advantages might seem small, but over time they can result in large improvements and some pretty strong bottom line business results, such as improvements in value life, an increase in production yield, and cost savings over time, as PTFE is a much more cost-effective material compared to most metals. And in the competitive world of pharmaceutical research and manufacturing, those small gains can add up to big wins for your company.

-

Low Frictional Resistance of PTFE: A Benefit in Bridge Bearing Design

Bridge structures are susceptible to a range of rigorous conditions. These include: repeated exposure to heavy loads traveling at relatively low speeds, potentially damaging weather elements, daily thermal cycles, and the occasional seismic event. These conditions require bridge bearing designs which can withstand a wide range of factors without compromising the integrity of the structure.

The ultimate responsibility of the bridge bearing is to allow for the controlled transfer of loads and the energy of movements from the bridge deck to the underlying bridge structures. While there are several general bearing designs available for these purposes, many highway bridges, which must accommodate large amounts of consistent traffic, benefit significantly from the inclusion of PTFE (polytetrafluoroethylene) slide bearings as opposed to those such as roller bearings.

PTFE on Stainless Steel Slip Style Bearing

PTFE on Stainless Steel Slip Style BearingOne of the most noticeable benefits of PTFE slide bearings in bridge design is the low frictional resistance it offers. PTFE is known for its remarkably low coefficient of friction [F=μN], and when combined with self-lubricating qualities, it becomes quite efficient at resisting those noted rigorous conditions.

Coefficient of Friction in Relation to PTFE

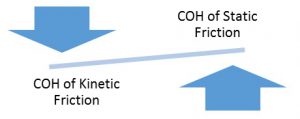

Friction is essentially the ratio of resistance between two objects that come in contact with each other. The measurement of this friction, the coefficient of friction (COH), shows the relationship between the two objects. Mathematically one can determine this relationship by applying the following formula:

F=μN

Where

F = frictional force

μ = coefficient of friction

N = normal force

These measurements can vary among same materials when comparing static friction to kinetic friction. When the coefficient is close to a value of zero (0), the friction is minimal. Such is the case with typical PTFE slide bearings. In fact, in terms of the broad availability of various engineering materials, PTFE offers the lowest coefficient of friction at an estimated COH of 0.04 for both kinetic and static friction, compared to a lubricated steel at 0.05 (kinetic) or 0.1 (static).

Slide bearing designs with PTFE are commonly used with stainless steel plates, and the PTFE is applied in one of two methods.

- The PFTE is applied between two flat stainless steel plates at a surface area smaller than that of the steel plates to avoid creep.

- The PTFE is applied to curved stainless steel surfaces to accommodate larger rotations (beyond 5 degrees).

Primary Benefits of PTFE in Bearing Design

Due to the low coefficient of friction, PTFE offers a significant benefit in bridge bearing design. In what is known as stick-slip action, two objects typically alternate between freely sliding against each other and abruptly sticking to each other. Usually this is the result of a difference in the coefficient of static friction when compared to the coefficient of kinetic friction, as demonstrated in Graphic A. The imbalance between the two causes a jarring effect.

Graphic A – Slip-Stick Action as the Result of Differences in COH

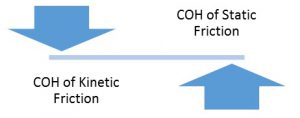

Graphic A – Slip-Stick Action as the Result of Differences in COHHowever, as previously stated, PTFE is unique in that the COH is minimally different (at typically 0.01 or less) between these two friction forces. In materials that have a greater range of COH between static friction and kinetic friction, more force is required to overcome the resistance, which results in that stick-slip motion. Thus, a significant benefit of PTFE slide bearings is the relative absence of slip-stick action, as shown in Graphic B.

Graphic B – Absence of Slip-Stick Action in PTFE Bearings

Graphic B – Absence of Slip-Stick Action in PTFE BearingsFurthermore, slip-stick action usually increases in correlation with COH increasing when the mating surfaces of the bearing become contaminated with debris. In applications of PTFE, however, the COH remains largely unchanged when the jointing between the steel plates becomes exposed to contaminants.

Additional Benefits of PTFE in Bearing Design

In addition to the benefits noted regarding resistance of slip-stick action, there are other advantages to choosing PTFE in bridge bearing design. PTFE bearings:

- Require little to no maintenance. There are no repeated maintenance cycles required once installed.

- Can handle temperature extremes, both ambient and friction generated, stable between -80ᵒF and 400ᵒF (although design must account for thermal expansion).

- Are largely unaffected by chemicals. Over time the bearings will not diminish in integrity due to exposure to various acids and solvents which may come in contact with the bearings.

- Are highly impervious to small particle invasion. Other bearing designs are susceptible to damage or increases in COH in these situations.

- Prove to be highly resistant to influences of weather extremes.

- Offer vibration damping to the bridge structure.

- Are less bulky than other mechanical bridge bear designs.

Low COH – The Most Significant Offering of PTFE

One of the most crucial considerations which needs to be made in bridge bearing design is that of the coefficient of friction. PTFE slide bearings are unique in their ability to offer extremely low COH in regards to both the kinetic and static friction levels, thus significantly reducing any stick-slip effect. As more and more bridge designs incorporate steel structures, the additional benefits of PTFE slide bearings become more clearly visible and worthwhile, especially over time.

International Polymer Solutions Inc. (“iPolymer”) machines fabricates a wide range of PTFE products for the global market. iPolymer utilizes the unique fluorine-enhanced properties of fluoropolymers like PTFE, PVDF, PFA and PEEK to develop solutions which challenge industry. Visit us at www.ipolymer.com

-

High Purity Polymer Solutions

iPolymer specializes in high purity polymer solutions for critical applications requiring fluoropolymer devices and fixtures.

iPolymer manufactures fluid and gas handling products for semiconductor, life science, sanitary and general chemical handling environments utilizing PTFE, PFA, PVDF, PEEK, Polypropylene and other polymers. Standard products includes pneumatic valves, solenoid valves, manual valves, air cylinders, spray guns, fittings & connectors. Please visit www.ipolymer.com