Valves are critical components in any industrial piping system. Of the many valve types, ball valves offer unique characteristics to control flow.

Ball valves are made up of a limited number of components, primarily: stem, stem nut, ball and body. From a Failure Mode & Effect Analysis (FMEA), the low component count greatly increases the ball valve’s mean time between failure. Ball valves are known for their robust durable characteristics and reliable performance. The most crucial component is the ball valve seat, which serves two functions: uniformly distribute the pressure induced stresses and maintain a good fluidic seal.

(FMEA), the low component count greatly increases the ball valve’s mean time between failure. Ball valves are known for their robust durable characteristics and reliable performance. The most crucial component is the ball valve seat, which serves two functions: uniformly distribute the pressure induced stresses and maintain a good fluidic seal.

Ball valves commonly are used as main shutoff or blocking valves in HVAC systems, chemical and water distribution systems, oil and gas process systems, food and sanitary process facilities, and pharmaceutical OEM devices.

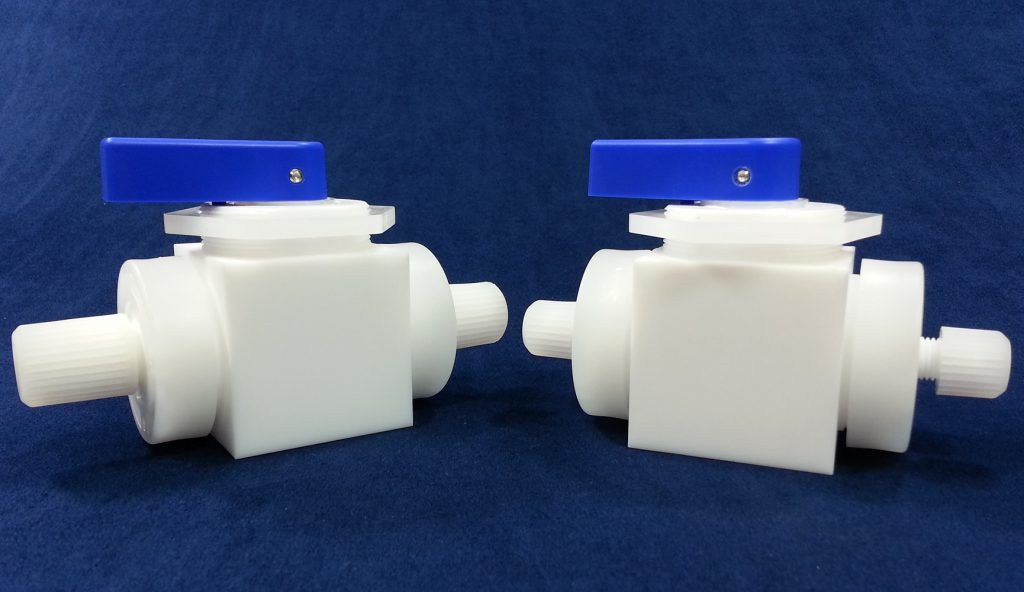

PTFE ball valves, like those engineered by iPolymer, feature an all-wetted surface design, ideally suited for harsh chemical and corrosive media, cleanroom and deionized water applications.

In this post, we consider the advantages and disadvantages of PTFE ball valves.

Advantages of PTFE ball valves:

- Require no lubrication and provide a tight seal with minimal torque. Because they require no lubrication, ball valves also can be used in corrosive media and without the potential for contamination.

- Provide fast, shock-free opening and closing and fully seal under a wide range of pressures and temperatures.

- Offer a long, maintenance-free service life. When a ball valve requires repairs, seats are easily accessible.

- Lightweight, and simple to install and operate. Ball valves also are a lower-cost solution compared to alternative valve types.

- Can be used in a wide range of industrial applications—particularly when strict maintenance and regulation of pressure and volume is required.

That said, there are some drawbacks to PTFE ball valves.

Disadvantages of PTFE Ball Valves:

- PTFE has higher expansion coefficient, sensitivity to cold plastic flow and comparatively poor thermal conductivity (good insulator). If the sealing surfaces are scratched, reliability of the seal decreases.

- While PTFE material can handle extreme temperatures, the thermal expansion properties will limit the useful temperature range (due to device assembly tolerances). For normal use, temperature swings should remain below 180°C.

- Regulating performance is generally less than that of pneumatic valves.

- Can underperform when used to regulate improper fluids, such as slurries containing solids, which can lead to wear, damage and jams.

- Not recommended for use in applications requiring sustained throttling.

Valves perform essential functions in every industrial piping system. iPolymer’s knowledgeable staff ensures you’ll get the right components for your system. Give us a call at 435.783.6040 for more information, or request a quote if you already know what you need.